What makes fine blanking special?

What happens during the cutting process?

Find out more here.

What is special about fine blanking and

what advantages does it offer?

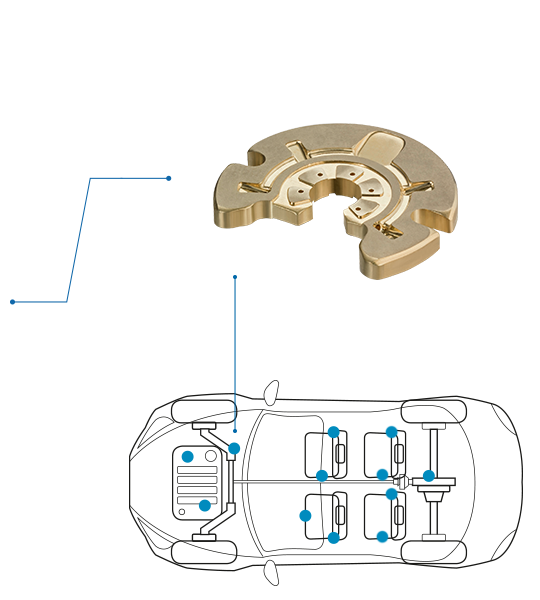

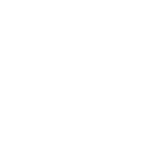

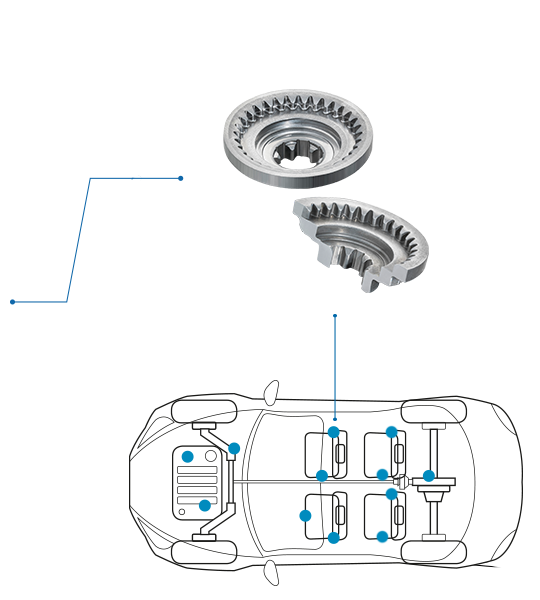

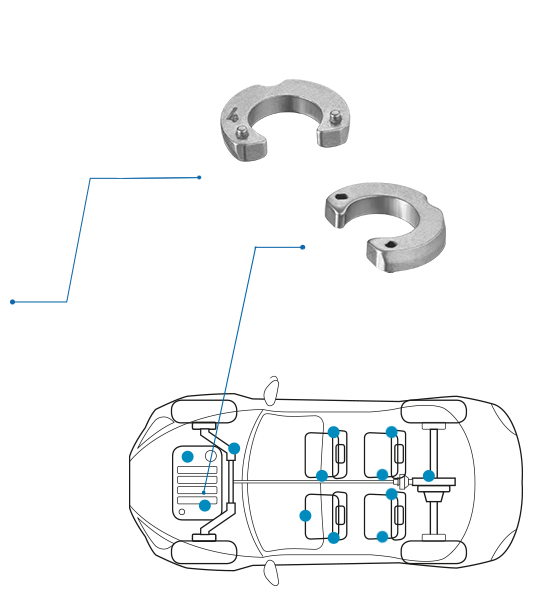

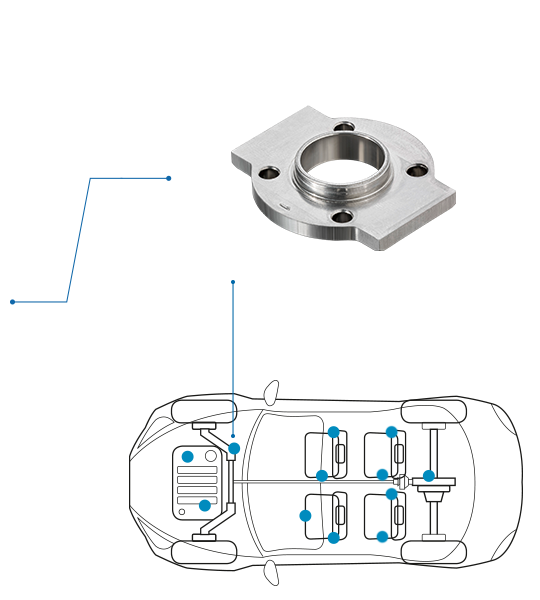

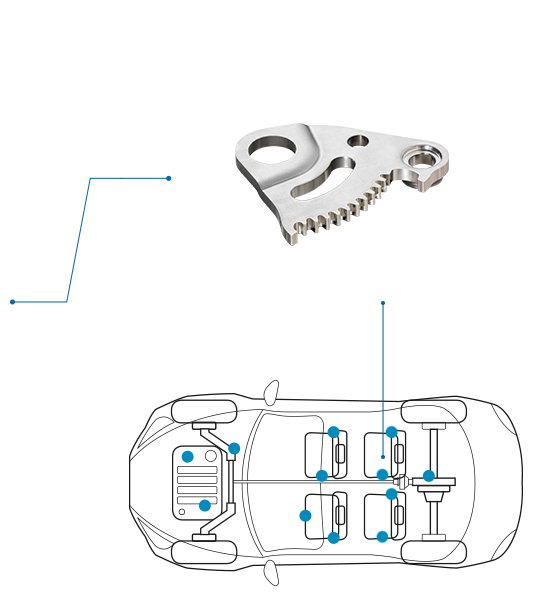

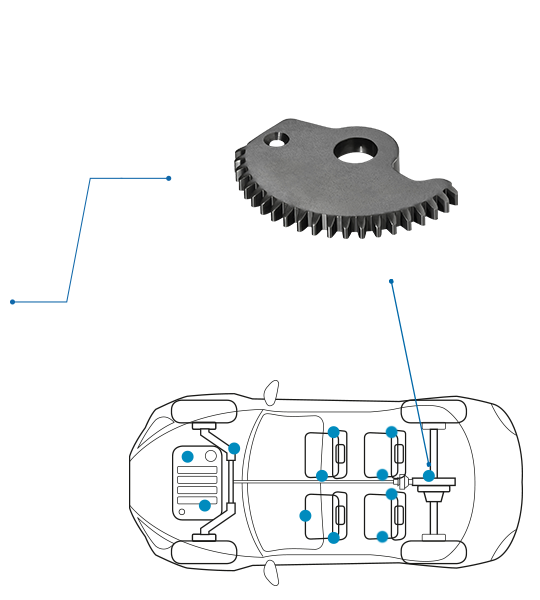

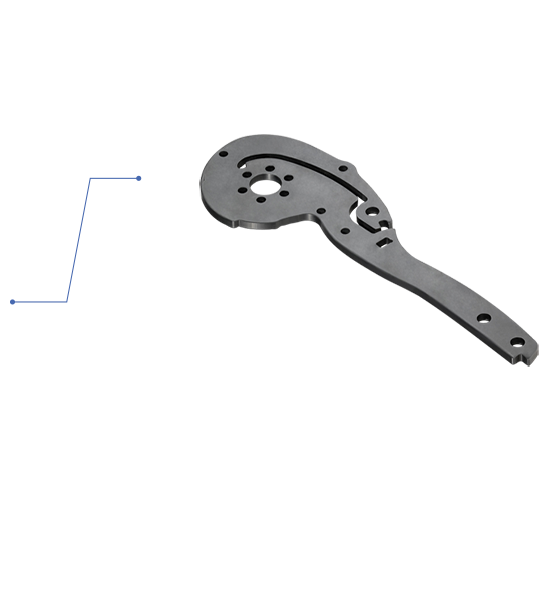

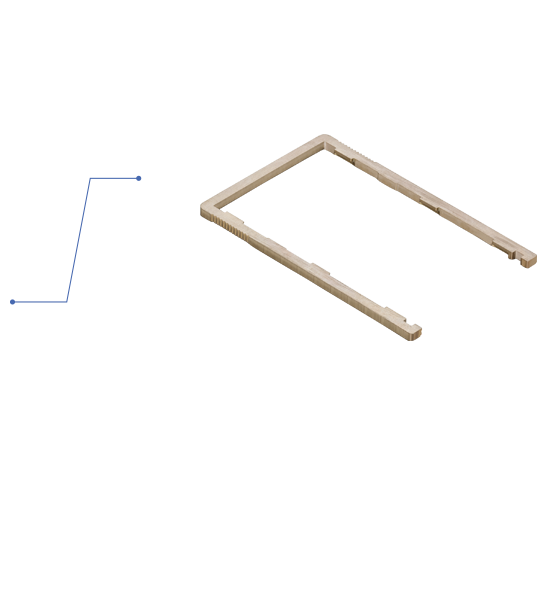

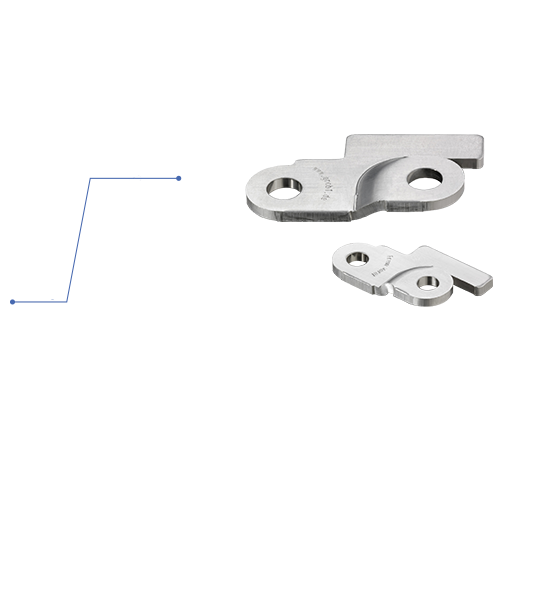

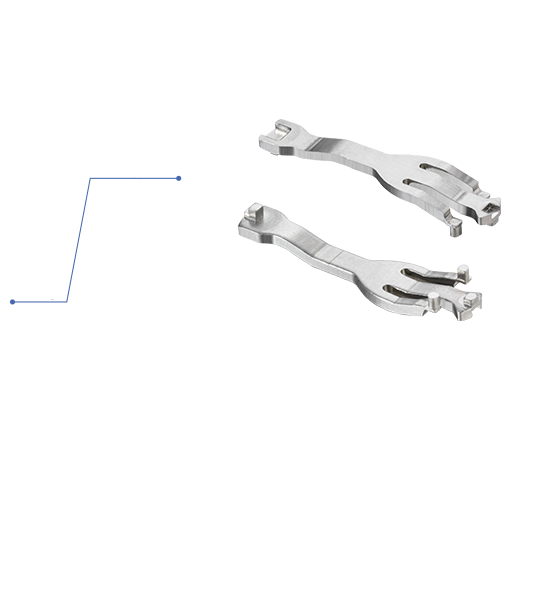

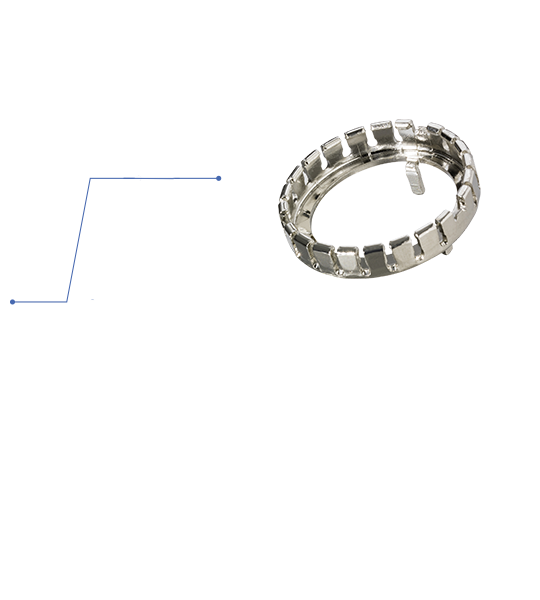

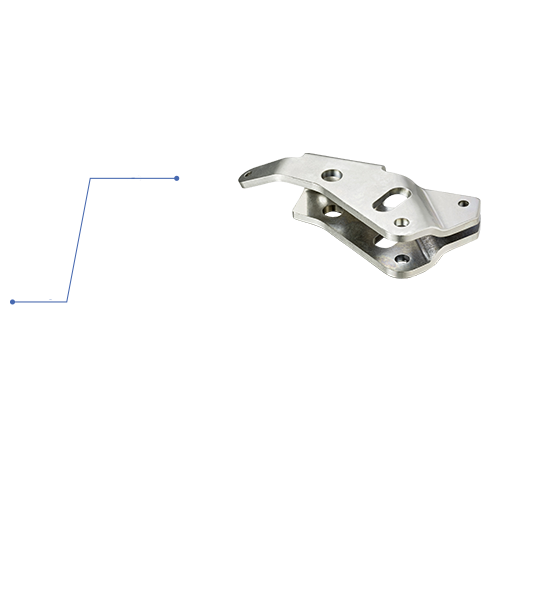

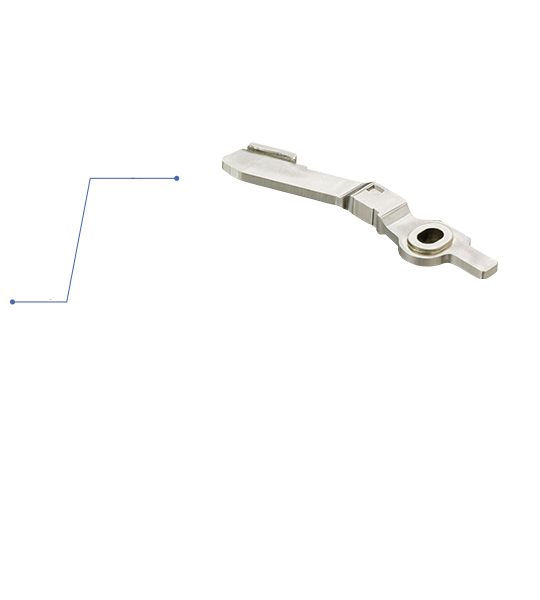

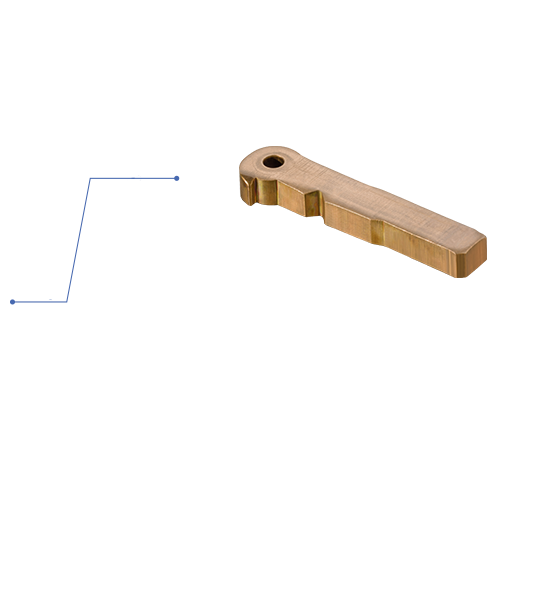

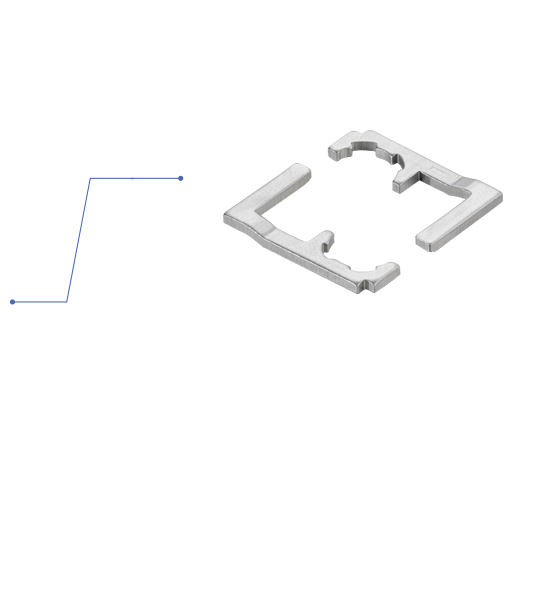

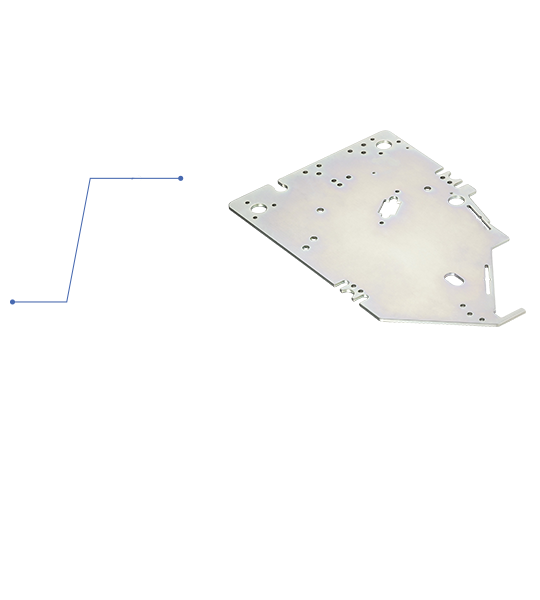

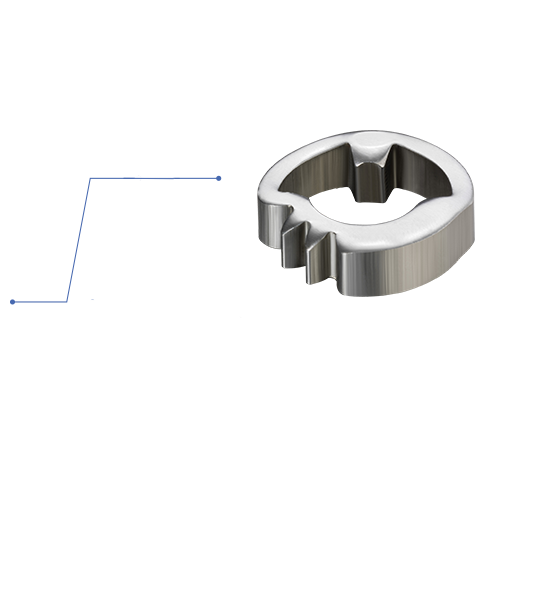

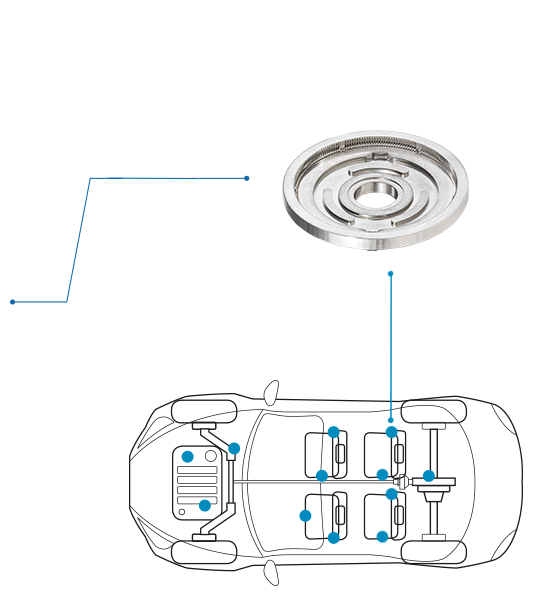

Fine blanking evolved from “normal” blanking. It was developed to produce high precision parts with flush cut surfaces and great repeatability. This is achieved by holding the sheet metal tightly between two surfaces during the blanking process and hindering material flow with the so called “stinger”. Furthermore, the specialized fine blanking presses enable us to produce complex geometries which can often be assembled without the need for further finishing steps.

Video fine blanking

A fine blanking machine in action

Contrary to punching, fine blanking requires a special press with three separate forces and a very precisely guided die punch. The following video shows a schematic representation of a punching process.